Pamarco anilox rolls for the flexo and corrugated industry

Corrusystems offers a selection of Pamarco anilox rolls for the flexo and corrugated packaging industry. Each anilox roll is tailored to specific production speeds, ink coverage, the substrate to be printed, and the complexity of the graphic image.

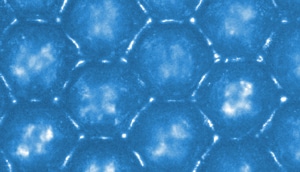

Anilox rolls consist of a steel or aluminium cylinder with an industrial ceramic coating. This layer is laser engraved with very fine holes, the anilox roll cells. The quantity, size, shape, and depth of the anilox cells define the amount of ink and its distribution on the printing plate.

Transfer volume and line grid L/cm (lines per centimetre) indicate the specifications and application of the anilox roll. For example, heavy ink layers, such as solid surfaces or block lettering, need line grids of 100-120 L/cm. Whereas a higher line grid of, e.g., 180-400 L/cm, gives finer details and is suitable for four-color printing, for instance, photos or detailed graphics.

Pamarco anilox technology

It is a challenge for flexo printers and converters to meet the increasing quality demands for packaging and displays, while still producing efficiently. That is why Pamarco continuously implements innovations in their anilox roll technology to help you deliver the highest print quality in a cost-effective way.

Independent tests, certified by Swansea and Clemson Universities, confirm that Pamarco’s anilox roll measurement and control systems guarantee the best repeatable and reproducible printing results.

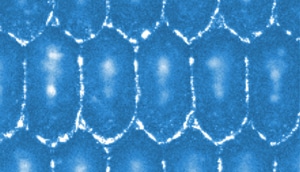

An example is Pamarco’s EFlo anilox roll. In contrast to the standard 60° honeycomb-shaped cell, the cells of the EFlo are 75º extended cell. As a result, the EFlo transfers 10-15% more ink volume than similar 60-degree engravings, which is ideal for higher solid coverage and fast press speeds. Furthermore, it reduces the chances of cell plugging.

Precision laser technology guarantees accurate anilox cell geometry

Through advanced, multi-hit laser technology, the ink transfer and colour matching of Pamarco rollers remain as accurate as with the first order, even after many print jobs.

Pamarco laser engraves the anilox roll cells to the highest screen resolutions and optimal cell volumes. This provides printers with an unlimited range of cell geometries for all graphic requirements.

Pamarco’s Process Data Archiving stores all cell engraving parameters which ensure that they are 100% comparable and repeatable.

Wear-resistant ceramic coating increases durability

Pamarco pays a lot of attention to the coating of the anilox rolls. The high-quality ceramic coating results in a consistent, wear-resistant anilox surface, which withstands scratches and scoring from doctor blades. Besides, the ceramic coating increases corrosion resistance.

Construction of the anilox rolls

Pamarco manufactures its own basic rolls from the best quality steel, stainless steel, and aluminium. In addition, Pamarco balances and tests each anilox cylinder separately. Certification guarantees high durability and optimal print quality throughout the entire lifespan of the anilox roll.

Pamarco flexo and corrugated board anilox rolls series

E-Flo

Anilox roller designed to work with CTP technology

- High performance anilox

- Consistent quality (Esko certified)

- High quality ceramic plasma coating

- Increased ink transfer

- Higher solid coverage

- Improved doctor blade lifespan

- Cleaner highlights

- Low dot gain

- Designed to run at higher press speeds

ThermaFlo

Solid-state multi-hit fiber optic technology

- Consistent cell geometry improves ink-release efficiency

- Easy to clean because of smoother cells, flatter cell bases

- Flatter cell walls provide better ink dosage

- Improved resistance to the scoring of doctor blades due to the surface hardness of ceramics

- Extended volume ranges through multi-hit technology

To select the right anilox roll and cell volume use Pamarco’s online cell volume calculator help or get in touch, I am happy to assist you.