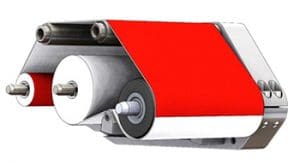

JB KleenPlate 3.0 on-press flexo printing plate cleaning

JB KleenPlate 3.0 performs automatic cleaning of the flexo printing plate throughout the entire job. By ongoing cleaning, KleenPlate prevents the printing plate from filling with ink and avoids dot gain. And all this without interrupting your print job.

Cleaning printing plates between print orders takes a lot of time. But even during the printing process, a lot of production time is lost to remove contaminants from printing plates. Think of piling, hickeys, bridging, etc. — everything that stands in the way of the desired printing results.

An additional task is manually removing and cleaning plates which cost 30 – 50% of production time. So, to maximize productivity and improve print quality, JB invented KleenPlate 3.0, an on-press flexo printing plate cleaning system.

KleenPlate 3.0 works in two options:

- Continuous DryKleen: dry application during the printing of the sheets.

- On-Demand WetKleen: full plate cleaning, applicable both during and after printing the order.

KleenPlate 3.0 DryKleen: continuous on-press plate cleaning

Continuous dry mode eliminates impurities in the printing image by constantly wiping the printing plate automatically at press speed. It uses a dry, non-abrasive, lint-free cloth consumable, which accurately removes a laminar ink film from the printing plate surface immediately after printing the sheet.

Minimal contact and no use of liquids prevent damage to your print reproduction or printing plate surface, whether it is a solid or fine screen.

Benefits of DryKleen continuous printing plate cleaning

- Eliminating impurities and preventing defects in the printing image.

- Cleaning of contaminated ink prevents color variation and dot gain.

- Preventing sticky ink avoids paper jams and plate wraps.

- Avoiding unnecessary cleaning stops maximizes up-time.

KleenPlate 3.0 WetKleen: automated on-demand cleaning

KleenPlate 3.0 WetKleen cleans your flexo printing plates both during and in between printing jobs. By automatizing the cleaning job, you gain considerable productivity.

And of course, KleenPlate 3.0 can also be fully integrated with JB Komand Center, the system that controls all JB-Machinery equipment simultaneously.

Contact us to discuss the benefits of KleenPlate 3.0 in your flexo process.