Asahi automatic flatbed die-cutting machines for corrugated board

Die-cutting creates the shape and foldability of a packaging box or display. Several factors play a role when deciding on the right type of die-cutter: substrate, speed, efficiency, and especially quality. Through sophisticated design and patented functionality, Asahi flatbed die-cutters excel in performance, ease of use, and accuracy.

Flatbed die-cutting in packaging

During the production of corrugated cardboard packaging and displays, flatbed die-cutting is essential. The die-cutter largely defines the appearance of a corrugated box or display.

Although laser and rotary die-cutting is also used in the packaging industry, flatbed die-cutting is the most economical way to cut and crease thicker substrates such as corrugated board.

The advantages of flatbed die-cutting for corrugated packaging include:

- Ideal for larger and thicker materials

- Sharp cuts

- Minimal material distortion

- Decreased tool costs

- Reduced lead times

Flatbed die-cutting procedures

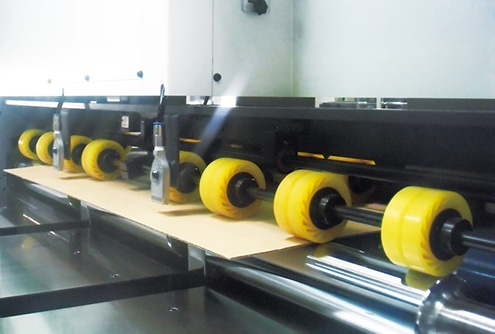

Asahi automatic flatbed die-cutters handle the following procedures in the production of corrugated cardboard packaging:

- Through cutting

- Creasing

- Kiss-cutting

- Perforating

- Stripping

Asahi’s patented functionality for unprecedented die-cutting accuracy

Asahi is trendsetting in die-cutting technology. Their first push-type flatbed die-cutter won a Tappi award for accuracy, sharpness, and productivity. Since then, Asahi has developed new techniques that further increase quality and efficiency.

For example, Asahi designed the patented LAP-feeder technology. Unlike die-cutters with conventional infeed, the LAP-feeder positions the bottom sheet first. This prevents any misalignment due to the weight of sheets on top of it, resulting in very accurate registration. Especially with pre-printed board, this is an important advantage.

Full digital control allows individual positioning

Asahi flatbed die-cutters monitor and register every movement and positioning of the material. The entire process can be followed digitally, whereby the input of individual sheets and parts of the material can also be controlled.

Quick-set: setting up for your next die-cutting order during production

In addition to the high precision die-cutting results, efficiency plays an essential role in responsible packaging production. But even within an already automated die-cutting system, Asahi offers additional options to avoid losing valuable time. For example, the ‘Quick-set’ option enables to set up the machine for the next order during a running order. This makes production loss due to setting-up a thing of the past.

Pre-loading and Cutting-chase options serve the same purpose: utilizing all production time, allowing the machine to continue processing the new order without pausing.

Asahi automatic flatbed die-cutting machines product range

Asahi flatbed die-cutting machines are available in various production widths and speeds. Several features to further enhance productivity are available as an option, for instance:

- Thin paper configuration (extra air fans, blow and suction)

- Sub-hoist at feeder section.

- Pre-loader (double entry)

- Quick-set

Asahi AP-1060

Features

- Suitable for a wide range of applications,

from thinner paper to even corrugated board - Left-hand configuration

7500

Max. 740 x 1060 mm

Min. 270 x 400 mm

730 x 1050 mm

764 x 1120 mm

Centerline II System

23.8 mm

8 mm

0.1-1.5 mm (to B-flute)

Asahi AP-1600 MII

Features

- LAP-feeder and TOP-feeder availability

- Suitable for E-flute to double-wall AB flute corrugated board

- Left- and right-hand configuration availability

5000

Max. 1100 x 1600 mm

Min. 450 x 600 mm

1080 x 1600 mm

1120 x 1648 mm

Centerline II System

23.8 mm

10 mm (adj. up to 20 mm)

11 mm

Asahi AP-1600 MIII

Features

- LAP-feeder and TOP-feeder availability

- Suitable for micro flute, single and double wall corrugated board, and laminated board

- Left- and right-hand configuration availability

6750 (LAP-feeder)

6000 (Top-feeder)

Max. 1100 x 1600 mm

Min. 450 x 600 mm

1080 x 1600 mm

1120 x 1648 mm

Centerline II System

23.8 mm

10 mm (adj. up to 20 mm)

11 mm

Asahi AP-1700

Features

- LAP-feeder

- Suitable for micro flute, single and double wall corrugated board, and laminated board

- Left- and right-hand configuration availability

5750

Max. 1300 x 1700 mm

Min. 450 x 600 mm

1280 x 1700 mm

1343 x 1740 mm

Centerline II System

23.8 mm

10 mm (adj. up to 20 mm)

11 mm

Asahi AP-2000

Features

- LAP-feeder

- Suitable for micro flute, single and double wall corrugated board, and laminated board

- Highly automated, ideal for large and medium-size converters

- Left- and right-hand configuration availability

6600

Max. 1100 x 2000 mm

Min. 500 x 700 mm

1090 x 2000 mm

1120 x 2040 mm

Centerline II System

23.8 mm

10 mm (adj. up to 20 mm)

11 mm

Asahi AP-2100

Features

- LAP-feeder

- Suitable for micro flute, single and double wall corrugated board, and laminated board

- AAS (Sheet Alignment System) as a standard feature

- Left- and right-hand configuration availability

7000

Max. 1300 x 2100 mm

Min. 500 x 700 mm

1280 x 2100 mm

1320 x 2135 mm

Centerline II System

23.8 mm

15mm (+/- 5mm for compensation)

9 mm

Please contact me to discuss your production requirements, I will be happy to advise you on choosing the right machine and the best options for your production process.