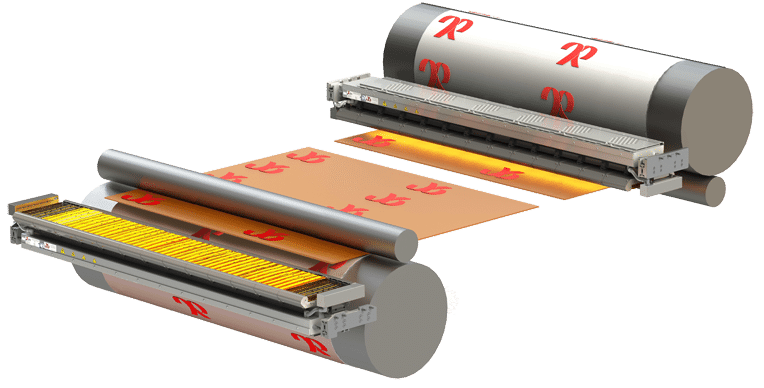

JB ColorDry: the safe and energy-efficient infrared dryer

Infrared drying speeds up the drying of your flexo inks considerably.

With ColorCure, JB-Machinery makes infrared drying faster, safer and more energy-efficient than ever.

Water-based inks dry by evaporation of water. This takes time, which is shortened by infrared drying. Infrared technology quickly evaporates the water in the ink through radiant heat.

Advantages of an infrared dryer for flexo print quality

Besides speeding up drying times, drying through infrared improves print quality by enhancing the stability of the ink during printing.

Another advantage of infrared technology is the improved trapping, and therefore color brightness and graphic quality. Furthermore, improved drying reduces or prevents smearing of the ink, ghosting and markings. All these improvements result in a reduction of waste and disapproved products.

How infrared technology boosts productivity in your printing process

Infrared drying also offers several advantages for your productivity, because it allows:

- printing at higher speeds

- printing, punching and folding in one order run

Creating new graphic- and printing choices with infrared drying

Additionally, infrared drying extends your market potential by expanding graphic and creative possibilities. This means you can offer:

- more choices in finishing’s and graphics

- printing on semi or fully-coated paper types

New and improved infrared technology – the benefits in your flexo process

Despite the advantages, the question arises as to whether infrared is not excessively high in power consumption. And even more important: how safe is the application of infrared technology when drying ink on flammable substrates?

To answer the first question: the advantages and savings of IR drying almost always outweigh energy costs. But because saving energy is vital from an environmental point of view, JB has developed ColorDry, the IR-dryer that is more energy-efficient and even dries more effectively than conventional dryers.

ColorDry is also the safest IR dryer available. Conventional infrared dryers generate high surface temperatures, whereas ColorDry’s infrared surfaces never exceed the self-ignition point of paper.

JB IR ColorDry: safe, energy-efficient, and effective

JB’s ColorDry includes several measures to make infrared drying safe, energy-efficient, and effective:

- switching the lamps on and off in less than a second

- the infrared dryer surfaces never exceed the auto-ignition temperature of paper

- stepless adjustment of light intensity/heat from 0 to 100%

- option to operate/select each infrared dryer cassette individually (only dry printed areas)

- Sentinel® monitors the entire surface, whether cardboard or paper lays on the dryer

- VisionMaster™ a dryer inspection and monitoring system that monitors what happens in the dryer’s area.

ColorDry is the most effective, safe, and energy-efficient infrared dryer system available. With over 3000 infrared dryers installed in more than 56 countries globally infrared dryers and seamless cooperation with the most well-known machine suppliers, JB drying installations are a standard in the corrugating and printing industry.

Corrusystems gladly helps you find the right solution for your application.